In an automobile assembly line workpiece identification

application, RFID readers can be used to identify and track various

components as they move along the assembly line.

RFID tags can be attached to each workpiece or component, which can

be read by the RFID reader as it moves past. This allows for

automatic identification and tracking of each component, ensuring

that it is properly assembled and installed in the correct

location.

The RFID reader can also transmit information to a central computer

system for real-time monitoring and analysis. This can help

identify any issues or bottlenecks in the assembly line, allowing

for quick corrective action.

RFID technology can also be used to ensure that all necessary

components are present before the assembly process begins. By

scanning RFID tags on each component at the beginning of the

assembly line, the system can verify that all required components

are present before beginning assembly.

Overall, the use of RFID technology in an automobile assembly line

workpiece identification application can improve efficiency, reduce

errors, and ensure that each component is properly assembled and

installed in the correct location.

Specification:

| Specification | |

| Support Standard | ISO 15693,ISO 14443 TypeA/B |

| Operating Frequency | 13.56MHz |

| Reading Range | 0-25mm |

| Communication mode | M:Modbus RTU232 R:RS232 |

| Communication rate | 10/100M bp |

| Power Supply | 24V DC(9-30V) |

| Current | <0.07A@24V DC |

| Physical parameters | |

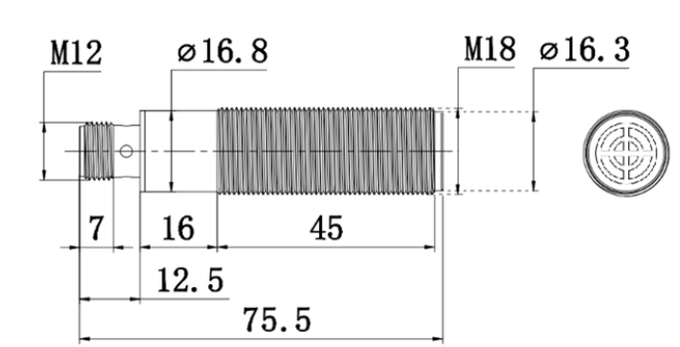

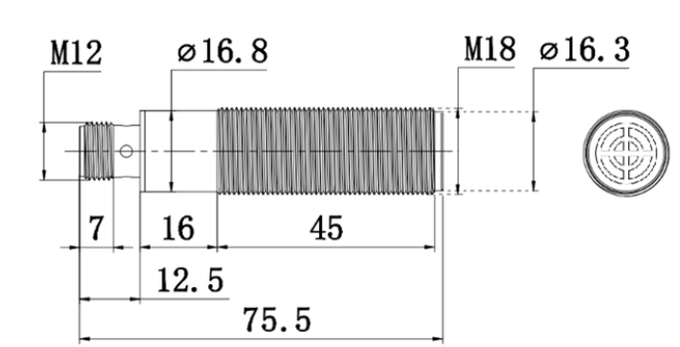

| Dimension | φ18mm*75.5mm |

| Weight | 50g |

| Fixed type | use two nuts to clamp on the site,or fixed in place by twisting |

| Housing Material | Brass nickel plating |

| Color | Sliver |

| Indicator light | LED*2 |

| Interface | M12A(4pin M) |

| Application environment | |

| Working Temperature | -40℃~+85℃ |

| Humidity | 5%~95%RH |

| Waterproof/dustproof | IP67 |

Application:

Intelligent Application of Home Appliance Manufacturing Process

Through RFID data acquisition technology (By adding RFID tags on

the product/tooling board and deploying RFID readers on the

workstation),the unmanned,automatic and real-time identification of

single-item products on the production line is realized.

Using real-time collected product information,complete error

prevention of mixed flow production materials,real-time push of

process guidance,automatic diversion of defective

products,automatic generation of quality reports,product

traceability management,mixed flow line alarms,and equipment

automation docking.

Engine Assembly Line

The reader can interface with various PLCs such as

Siemens,Schneider and Mitsubishi through the industrial bus

controller. By reading the RFID tag mounted on the tray,passing the

information to the PLC, Through the information of installation to

guide the assembly robot or the assembler to auto select the

appropriate part,the engine assembly efficiency can be greatly

improved.

Factory Automation

This product has always been a key player in the field of discrete

manufacturing with its strong portfolio comprising sensors,

connection and fieldbus technologies, RFID and control solutions.

Our comprehensive solutions help our customers to improve

efficiency, increase availability and minimize errors.

Dimension Drawing(mm):

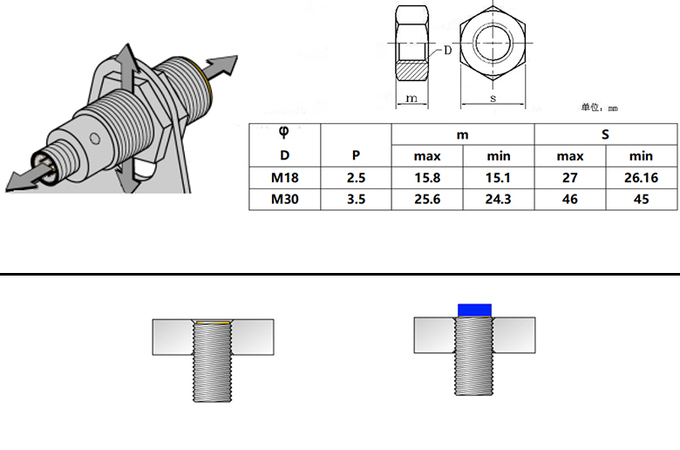

Installation Instruction:

The product comes with M18*45mm thread. When fixing, use two nuts

to clamp on the site,or fixed in place by twisting. If the

application environment is not allow, we can support bracket to

install.

When there are more than two readers to be installed, the distance

between the readers needs to be greater than 850mm.

FAQ

1.How we can trust you?

We are Alibaba Trade Assurance Supplier and 2 years Ali Gold

Supplier

We focus on HF RIFD equipment for 10 years.

Our products have 17patens and copyrights certificates.

Our company has approved ISO9001-2008 quality management system

certificate.

Our company is awarded High and New Technology Enterprise and

Science and Technology Innovation Small Giant Enterprise by Chinese

government.

2. What’s your delivery time?

Around 2~10 working days according to exact order quantity and

stock situation.

3. What's your MOQ?

Big Order or Sample Order is accepted by our company.

We understanding new customers may take sample testing to know our

quality and service.

4. Why choose us?

With us make Win-Win Business Situation!!!

24 *7 hours after sales service

We accept "PayPal", credit card to convenient customer make

payment.

Quality Assurance Contract

Full refund in case of bad quality

Online supports if any technique issue.

Both Small Order and Big Order are accepted.

Accept OEM/ODM order.

5. What is the warranty?

3 years warranty for core device from the date of delivery,A

lifetime technical support.

We will return full money to customer if we did not shipping right

items as contract.